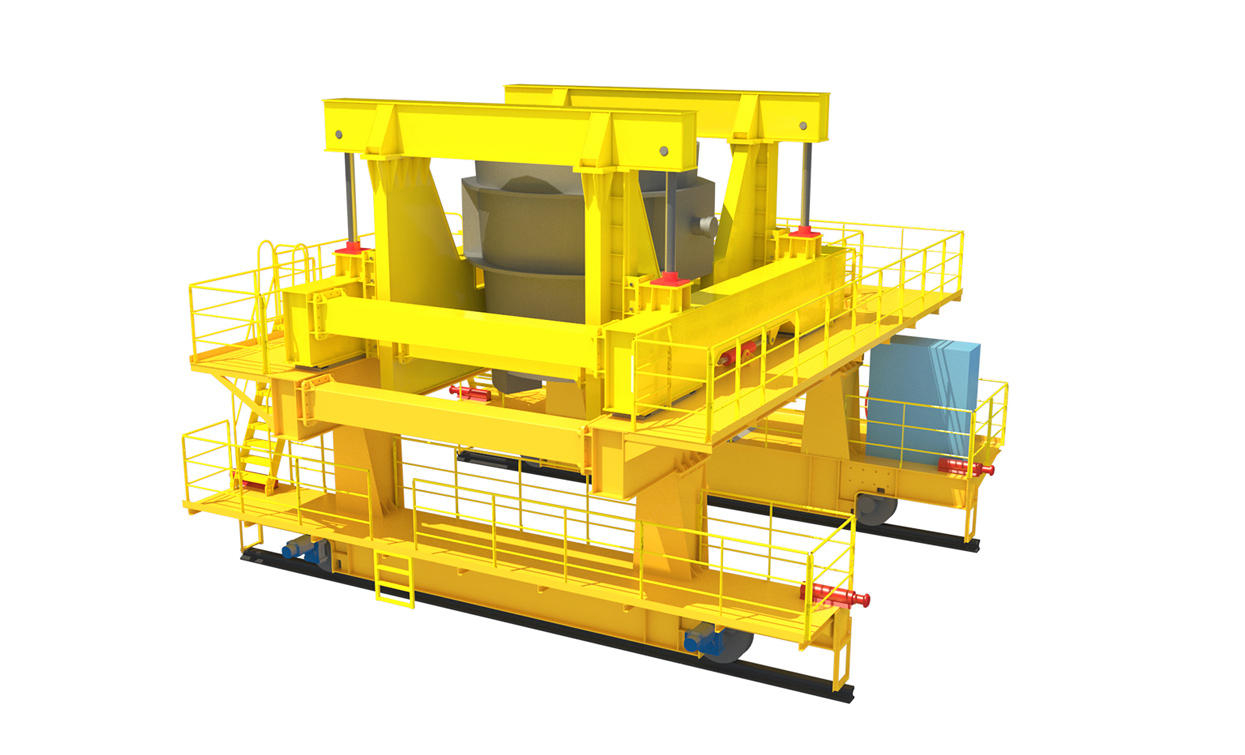

The ladle transfer trolley is used in metallurgical workshops for transporting ladle, adding molten metal to electric furnaces, centrifuges or molds. This product adopts ground rail walking, direct flowing or dumping method to handle ladles. It is suitable for new cast production lines and old production line transformations, which is fully automated. The current station pouring is completed, and it automatically runs to the next station for pouring.

This machine is equipped with a ladle lifting and translation system to adapt to different ladle and casting molds. It is equipped with a hydraulic system that controls the opening degree of the direct-flowing port of the ladle to adjust the pouring speed in real time to ensure the pouring quality. Compared with the traditional aerial driving pouring technology, it has higher safety, controllable pouring speed, high pouring quality, low manual labor intensity, 30% improvement in efficiency, and 20% reduction in operation and maintenance costs.